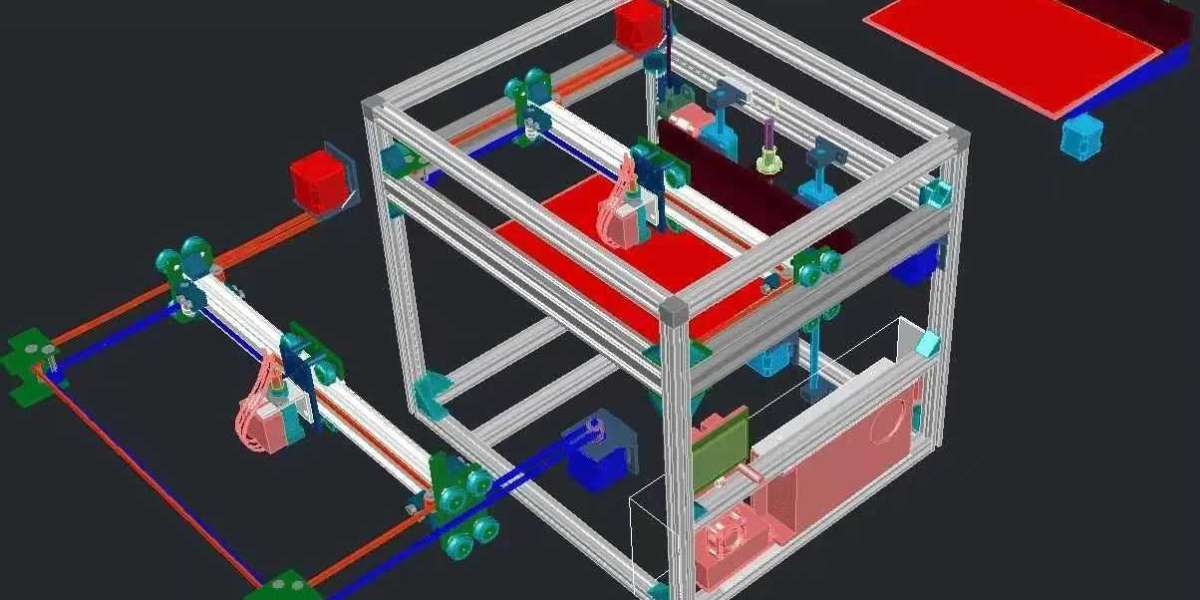

Core XY printer as a high-precision 3D printing equipment, its print quality directly affects the performance and appearance of the final product. In order to improve the print quality of Core XY printers, we need to adjust and optimize from many aspects.

Ensure the mechanical structure of the printer is stable and accurate.

The moving parts of the Core XY printer need to be checked and calibrated regularly to ensure smooth movement of the X and Y axes without jitter. You can use a level to detect the levelness of the printing platform and correct it by adjusting the foot pad. At the same time, check whether the belt is loose, whether the tension is moderate, and adjust or replace it if necessary.

Optimize print head temperature and speed Settings.

The temperature of the print head is critical to the melting and forming of the material. According to the characteristics of the material used, set the appropriate printing temperature, generally need to find the best value through several tests. At the same time, set the printing speed reasonably, too fast speed may lead to the loss of model details, too slow speed will affect the efficiency. Generally, when printing fine models, reducing the printing speed can improve the print quality.

Select the appropriate printing materials and slicing software.

The quality of the printing material directly affects the printing effect, and the selection of materials with good quality and uniform diameter can effectively avoid plugging and breakage in the printing process. Slicing software is a key tool for converting 3D models into printer recognizable instructions, and choosing a powerful and rich set of slicing software, such as Cura or Simplify3D, can further optimize printing parameters and improve print quality.

Maintain and clean the printer regularly.

The long-term use of the printer will lead to the accumulation of dust and residue, affecting the normal work of the print head. Use compressed air to clean the inside of the printer, especially the print head and feed mechanism parts, to ensure that it is clean and free of debris. In addition, regularly check whether the nozzle is blocked, and clean or replace it in time.

Through the above adjustment and maintenance, the print quality of the Core XY printer can be significantly improved, and more fine and stable printing results can be obtained.

There are also some printer maintenance tips that I have summarized

Spare parts management: Keep some critical spare parts, such as sprinkler heads, belts, etc., for quick replacement when needed to reduce downtime.

Ambient temperature control: maintain the stability of the working ambient temperature of the printer to avoid excessive temperature fluctuations affecting the printing accuracy and material properties.

Upgrade firmware: Check and update your printer's firmware regularly for better performance and support for new features.

Use print log: Use the print log function to record the parameters and results of each print, which is easy to analyze and improve the printing process.

Professional training: Regularly train operators to improve their proficiency in printer operation and maintenance and reduce failures caused by improper operation.

With these tips, you can better maintain the Core XY printer, ensure its long-term stable operation, and continue to provide high-quality printing results.