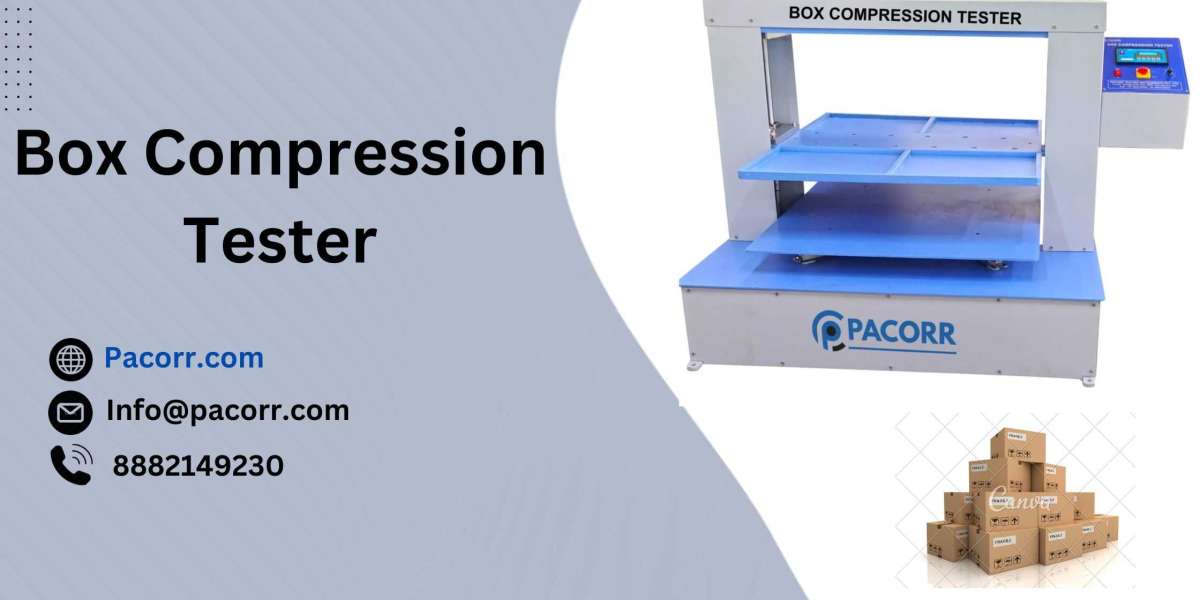

Understanding Box Compression Testing

Box compression testing is a method used to determine the compressive strength of packaging materials, particularly corrugated boxes. This test measures the maximum load a box can withstand before collapsing. The data obtained from this test helps manufacturers design packaging that can endure the rigors of shipping and handling, thus preventing product damage and ensuring safe delivery.

Importance of Box Compression Testing

Product Protection: Ensuring that packaging can withstand the stresses of transportation and storage is crucial for protecting the contents. A robust Box Compression Testing helps identify potential weaknesses in packaging designs.

- Cost Efficiency: By optimizing the strength of packaging materials, manufacturers can reduce costs associated with product returns, replacements, and damage claims.

- Compliance with Standards: Many industries have stringent packaging standards. The Box Compression Tester ensures compliance with these standards, facilitating smooth business operations and market access.

Key Features of the Box Compression Tester

- Precision and Accuracy: Modern box compression testers offer high precision and accuracy, providing reliable data that manufacturers can trust.

- User-Friendly Interface: Advanced testers come with easy-to-use interfaces, enabling operators to perform tests efficiently without extensive training.

- Versatility: These testers can handle a variety of box sizes and types, making them suitable for different industries, from food and beverages to electronics and pharmaceuticals.

- Durable Construction: Built to withstand heavy use, box compression testers are designed for long-term reliability and performance.

- Automated Testing: Some models offer automated testing features, reducing human error and increasing testing efficiency.

Applications of the Box Compression Tester

- Quality Control in Manufacturing: Ensuring that each batch of boxes meets the required strength specifications is critical for maintaining product quality.

- Research and Development: Packaging engineers use the tester to develop and refine packaging designs, improving durability and performance.

- Logistics and Supply Chain Management: Companies in the logistics sector use box compression testers to select the best packaging materials for their needs, minimizing damage during transit.

- Compliance Testing: Meeting industry standards and regulations is essential for market access. The tester helps in verifying that packaging materials comply with these requirements.

Benefits of Using the Box Compression Tester

- Enhanced Product Safety: With accurate testing, manufacturers can ensure that their packaging provides adequate protection, reducing the risk of product damage.

- Improved Customer Satisfaction: Delivering products in pristine condition leads to higher customer satisfaction and loyalty.

- Cost Savings: By preventing damage and reducing returns, companies can save significantly on costs associated with product replacements and repairs.

- Competitive Advantage: High-quality packaging can set a brand apart from its competitors, enhancing its reputation in the market.

Conclusion

The Box Strength Tester is an invaluable tool for manufacturers and logistics providers aiming to ensure the durability and strength of their packaging materials. By investing in a reliable box compression tester, companies can enhance product safety, improve customer satisfaction, and achieve cost savings. In an era where packaging integrity is more important than ever, the Box Compression Tester stands out as a critical component of quality control and product development processes.

FAQs

Q1: What is a Box Compression Tester?

A: A Box Compression Tester is a device used to measure the compressive strength of packaging materials, particularly corrugated boxes. It determines the maximum load a box can withstand before collapsing.

Q2: Why is box compression testing important?

A: Box Compression Tester Price is crucial for ensuring the durability and strength of packaging materials. It helps prevent product damage during shipping and handling, reduces costs associated with returns and replacements, and ensures compliance with industry standards.

Q3: What features should I look for in a Box Compression Tester?

A: Key features to look for include precision and accuracy, a user-friendly interface, versatility to handle different box sizes, durable construction, and automated testing capabilities.

Q4: How does the Box Compression Tester benefit manufacturers?

A: It enhances product safety, improves customer satisfaction, reduces costs associated with product damage, and provides a competitive advantage by ensuring high-quality packaging.

Q5: Can the Box Compression Tester be used for different industries?

A: Yes, it is suitable for various industries, including food and beverages, electronics, pharmaceuticals, and logistics, due to its versatility in handling different types of packaging materials.

Q6: How does box compression testing contribute to cost savings?

A: By preventing product damage and reducing the number of returns and replacements, box compression testing helps companies save on costs related to repairs and customer service.

For more information about the Box Compression Tester and other quality testing equipment, visit Pacorr Testing Instruments.